As part of Singapore Green Plan 2030 to quadruple solar energy deployment by 2025, large-scale deployment of solar photovoltaic systems is expected. In view of the hazards/risks associated with the activity of installation of solar photovoltaic systems at height such as falling from height, companies need to address WSH risks to ensure workers can install such system safely

Introduction

Under the Singapore Green Plan 2030, Singapore aims to have cleaner and better use of energy and become more energy efficient. One of the targets is to quadruple solar energy deployment by 2025, including covering HDB roof tops with solar panels, so that by 2030, solar energy deployed will be five times that of today. At its peak, the solar energy generated can power about 350,000 households a year.

This means that large-scale deployment of solar photovoltaic (PV) systems across the island is expected in the years ahead.

The best place for solar PV systems to be installed in land-scarce Singapore is on the roofs of commercial and residential buildings. Hence, rooftops will become a typical workplace setting and demand for competent contractors to complete these installation works will rise accordingly.

In view of the upcoming demand, companies should take the following into consideration to ensure companies and workers can work safely.

Pre-installation of the Solar PV system

The first step is to select the right solar installer and roof work contractor (if engaged). Ensure that both have the sufficient knowledge, qualifications, equipment, skills, and safe systems of work that comply with the WSH legislations.

The solar installer and roof work contractor must perform the following checks before starting onsite installation of the solar PV system: • Survey the actual worksite, i.e. the roof and surroundings; • Conduct worksite-specific risk assessment, such as inspecting the roof for structural integrity issues such as sharp edges, rot, or a sagging roof; • Assess the slope and pitch of the roof to evaluate the risk controls needed to ensure the safety of workers and the stability of the equipment used; and • Implement appropriate risk controls, such as temporary edge protection, scaffolding, mobile elevating work platforms, exclusion zones, and access to the roof or mechanical lifting aids.

Installation of the Solar PV System

The solar installer must survey the actual worksite to determine that the roof is suitable and safe for the installation. Critical checks for suitability include:

- Confirming that the roof can support the additional loading imposed by the solar PV system, as well as the workers and their equipment;

- Checking that there are no open sides or whether it is possible to install edge protection at all open sides and openings;

- Inspecting the roof condition and making the necessary repairs before allowing installation works to begin;

- Ensuring there is sufficient space to be allocated as designated accessways between solar panel groups;

- Verifying that designated accessways are free of hazards e.g. fragile surfaces.

- Installing systems at safe distance from fall and electrical hazards, and allowing for a safe means of access, where reasonably practicable.

- Select a solar PV system that requires low or no maintenance alternatives where available, for example plastic wire ties would require replacement whereas coated metal ones may not

- Select a modular system with removable panels and components for easy replacement;

- Install a remote monitoring and control system to reduce the need for rooftop visits;

- Deploy drones for site inspection;

- Ensure that sufficient space has been allocated for maintenance equipment and onsite activities;

- Label and mark all electrical components properly; and

- Design a system to facilitate the isolation of individual panels

- Identify, mark, barricade and communicate the presence of fragile surfaces;

- Cover the fragile surface with a secure cover or provide all-round barricades;

- Provide workers with a way to work under, e.g. using a tower scaffold, or above the fragile surface, e.g. using a mobile elevated work platform;

- Install roof ladders, gangways, crawl boards and roof brackets to facilitate movement on sloping roofs; and

- Deploy safety nets below fragile surfaces.

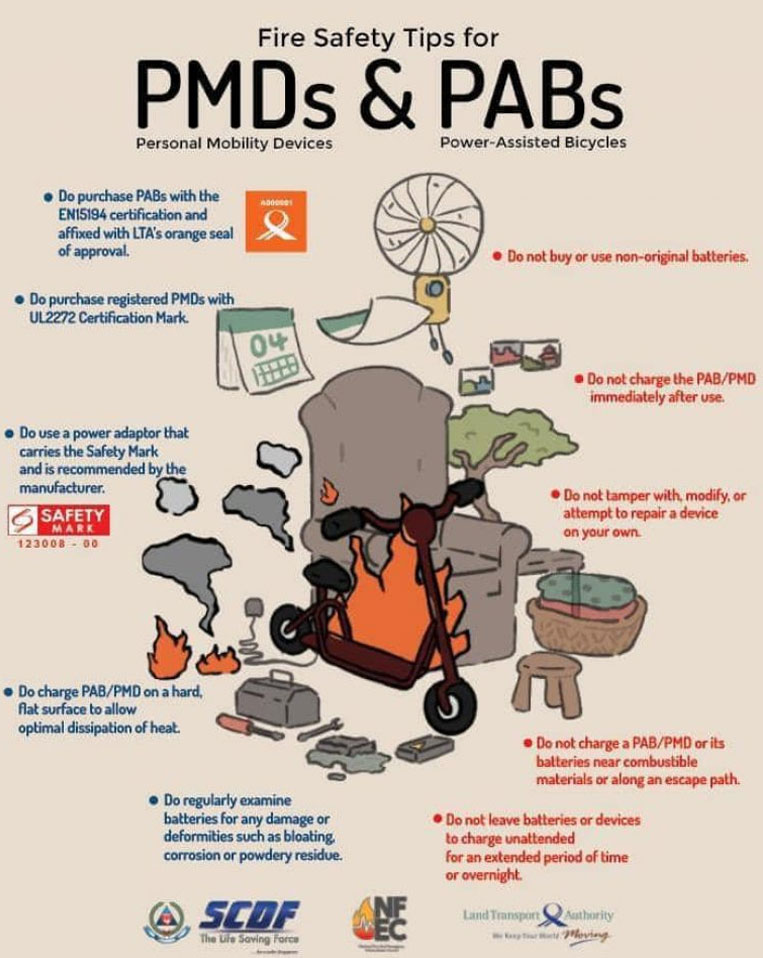

Image from SCDF on Facebook.

Image from SCDF on Facebook. Image from SCDF on Facebook.

Image from SCDF on Facebook. Image from SCDF on Facebook.

Image from SCDF on Facebook.