INTRODUCTION

What is WSH Reporting?

WSH reporting is the provision of WSH information by companies in their annual reports.

The content for reporting can be broadly categorized into WSH performance, policies, and targets. Although the law does not mandate companies to report their WSH information, the Workplace Safety and Health Council considers this a good practice to adopt.

Why report on WSH in Annual Reports?

In today’s highly globalized world, there is growing demand for increased corporate transparency and accountability. Organizations face increasing pressures for more disclosures on various aspects of their corporate performance that includes social, ethical and environmental considerations.

There is an increasing recognition that WSH reporting contributes to good corporate governance as it is a key component to improve corporate disclosure. Reporting on WSH issues demonstrates a company’s commitment to effective workplace WSH management for the prevention of injuries at the workplace. The company’s open approach to managing WSH matters enhances organizational credibility among their investors.

WSH reporting also enhances the corporate social responsibility (CSR) profile of companies. WSH forms an integral part of CSR. CSR essentially integrates economic, social, ethical and environmental concerns in business operations. The major social concerns include the welfare of key stakeholders in an organization; especially employees.

Therefore, safety and health at work, as part of employees’ well-being, places WSH as a key component of any corporate CSR agenda.

Today, CSR has gained momentum as an important priority for companies and is being mainstreamed to form part of business performance monitoring and reporting. Many reporting guidelines and tools for measuring CSR performance also incorporate WSH issues. Therefore good WSH performance and practices can be leveraged as a positive aspect of CSR for corporate branding and creating stakeholder value.

Business benefits for WSH Reporting

More companies are beginning to accept that good WSH management can be leveraged as an indicator of good business performance. Companies which have good WSH performance benefit from reduced loss time in production and this translates to better productivity and business performance. The potential returns from WSH reporting include the following:

• Creates transparency on WSH performance that could be leveraged to drive further improvements. This also creates confidence in investors that the company is taking active measures to improve its safety and health performance and thereby its productivity.

• Provides basis for recognition of the employees’ contributions to WSH and reinforces the company’s values and culture

• Shows a company’s commitment to broad-based, corporate performance improvement, with WSH as a key business objective

• For companies which have achieved high WSH standards, a positive WSH profile would enhance their profile and provide a competitive advantage

Monitoring WSH performance to reinforce WSH reporting

In addition to WSH reporting, companies with good WSH practices also regularly monitor their performance for continual WSH improvement. To help companies track their WSH performance, we have suggested a list of leading WSH indicators in Annex A which can be used to monitor and provide advance indication of the effectiveness of their safety management systems.

How to report?

This set of guidelines will help companies to report on safety and health matters in their annual reports. We recommend that good WSH reporting should comprise information on WSH performance, active management of the safety and health of workers and proposals for continual improvement.

There is no single standard for WSH reporting. Companies which are new to WSH reporting may choose to start with reporting the key WSH information in the safety section of their annual report. The recommended reported information can be found under Basic Reporting (See Annex B). As companies gain more experience in WSH reporting, the WSH Council strongly encourages companies to extend WSH reporting by including more information recommended under Additional Reporting (see Annex C) .

There are many ways of presenting your organization’s WSH information. A template for basic WSH reporting can be found at Annex D. Companies may also wish to report their WSH information within the context of overall CSR reporting. The Global Reporting Initiative (GRI) sets out the guidelines for CSR reporting. However, companies are encouraged to report their WSH performance beyond the recommendations covered in the GRI Guidelines by incorporating Council’s WSH reporting guidelines within their CSR reporting.

ANNEX A

LIST OF SUGGESTED LEADING INDICATORS ON WSH

BROAD CONTEXT OF COMPANY’S POLICY ON WSH

• Whether the WSH policy has been published and adequately communicated for e.g. in safety committee meetings

• % of management and supervisors’ job descriptions that contain specific health and safety responsibilities

MANAGING WSH

Statutory compliance

• % of applicable legislation addressed by Company procedures

Risk Control

• Number and % of jobs for which risk assessments are carried out

• Number and % of risk assessments updated as a result of changes in work-scope

• % of Safety Management System that is compliant with current guidance (BS 8800; OHSAS18001)

Communication of WSH responsibilities for accountability

• Extent of communications of safety policies and targets to employees and stakeholders

• % of safety committee meetings conducted against scheduled meeting requirements per month

• Number and % of safety tours by senior managers and/or management per month

Integrating WSH in business practices

• Number and % of contracts with WSH requirements (e.g. bizSAFE requirements)

WSH PROGRAMMES AND INITIATIVES

Areas for WSH improvement

• Number and % of jobs with hazard assessments

• Number and % of safety gaps addressed

• Number and % of additional control measures identified at site during execution of work

Staff participation in WSH initiatives

• % of staff participation in national WSH events and committees

Workplace Health initiatives

• % reduction in exposure hours for hazardous activities

• % reduction of health risks at design stage by including standards (e.g. for noise and substance emissions) in procurement contracts

• % of workplace health issues addressed in safety briefings held per month

WSH INCIDENTS

Audits and inspections

• Number and % of audits completed against planned requirements per month

• Number and % of work site inspections carried out against planned requirements per month

Incident management

• Total number of WSH incidents reported

• % of WSH incidents management closed within targeted timeline

EMPLOYEE INVOLVEMENT

WSH Training

• Number and hours of training courses run

• % of training budget set aside and utilized for WSH training

• % of staff for WSH course attendance (average)

• Total number of safety days scheduled and held every month

• % of identified staff competency gaps addressed

Employee contributions on WSH

• % of staff involved in teams for WSH innovation

• % staff suggestions implemented for safety improvements

REPORT ON WSH PROGRESS AGAINST TARGETS

• % of WSH plans and objectives that have been set and achieved

MANAGING CONTRACTORS

• Whether guidelines available for contractor management

• Whether contractor management guidelines have been adequately communicated

• Whether procedures in place to ensure effective implementation of contractor management guidelines

ANNEX B

BASIC REPORTING

A. WSH Statistics

WSH statistical indicators serve as a useful gauge of your company’s WSH performance.

The following indicators should be included in your WSH reporting. For some, it is preferred to present the data as frequency rates as this helps with comparing against previous performance, your long-term safety targets and national averages.

1. Workplace Injuries2

Workplace Injury Rate

= No. of Fatal and non-Fatal Workplace Injuries x 100,000

No. of employed Persons

2. Occupational Disease (OD)3 Cases

Occupational Disease Incidence

= No. of Occupational Diseases (i.e. chronic confirmed cases) x 100,000

No. of Employed Persons

3. Frequency of Workplace Accidents4

Accident Frequency Rate (AFR)5

= No. of Workplace Accidents Reported x 1,000,000

No. of Man-hours Worked

4. Number of Man-days Lost Due to Workplace Accidents

Accident Severity Rate (ASR)

= No. of Man-days Lost to Workplace Accidents x 1,000,000

No. of Man-Hours Worked

2 A workplace injury is any personal injury, disease (acute) or death resulting from a workplace accident.

Workplace Injuries cover those sustained by employees and:

i. Resulting in more than 3 consecutive days of medical leave; o

ii. Resulting in at least 24 hours of hospitalization

3 An Occupational Disease (OD) is a chronic disease contracted as a result of an exposure over a period of time to risk factors arising from work activity. A confirmed case of occupational disease is one where there is definite evidence that the worker has suffered from a disease which is related to his occupation. List of ODs can be found in the Third Schedule of the Workplace Safety and Health Act.

4 A workplace accident is an unexpected and unplanned occurrence, arising out of or in connection with work which results in one or more workers incurring a personal injury, disease (acute) or death. They cover those resulting in the

i. Death of Employees, self-employed persons and persons not at work

ii. Injury of self-employed persons and persons not at work who have to be taken to the hospital for treatment

5 A measure of how often workplace accidents take place

5. Number of workplace Fatalities in the Reporting Period

6. Estimated Financial Cost to company of work related injuries, illnesses suffered by staff and incidents in the reporting period

B. WSH Management Systems

To give a more holistic picture of your company’s WSH performance, it is best to complement your numerical reporting with information on your company’s WSH policies, plans and strategies. It also provides the information needed to drive safety improvements.

1. Broad context of your company’s policy on safety and health

Provide a brief overview of your company’s safety and health policy. It sets out your company’s general approach, objectives and arrangements in place for managing WSH.

This could comprise but not limited to the following:

• Company’s policy on WSH

• Statement by the Chief Executive / Board on commitment to WSH

• Board level responsibilities

• Broad Communication and implementation strategies for its WSH policies and targets

2. Managing WSH

Describe how WSH is managed in your workplaces. This could include:

• Programmes to enable statutory compliance

• How hazards and risks are systematically assessed and controlled

• How WSH responsibilities are assigned and communicated to ensure clear accountability.

• How WSH is embedded in business practices

3. WSH programmes and initiatives

Outline the company’s key WSH programmes which which may include the following:

• Priority areas targeted for improvement and reasons for selection

• Participation in national WSH related events and programmes such as bizSAFE ,and representation in national safety committees or taskforces

• Workplace Health policies and programmes such as education, training, preventive and risk control programmes in relation to occupational diseases; arrangements to promote workers’ rehabilitation after injury or illness, and the outcomes

4. WSH accolades and awards

Report on any safety awards or certificates your company has received in recognition of your WSH achievements. This could consist the following:

• Achievement of any WSH management accreditation

• WSH Awards received for stellar WSH performance by company, safety committee or representative

• Nomination / Awards by other internationally recognized safety agencies

5. WSH incidents

For any significant incident, including near misses, provide information on the circumstances concerning the incident, company’s responses and post-incident actions to prevent recurrence of the incident. This could also include

• The impact of the incident to the organizational staff morale; the family and relatives of the deceased employee, business operations and the business cost incurred

• Other actions taken such as welfare arrangements for the deceased worker’s family,

• An analysis of the incident and the key learning points

6. Employee involvement, contributions and WSH training for staff

Share on the company’s WSH initiatives or projects involving employees including:

• Availability and accessibility of information to employees on WSH

• Description of the WSH training provided for all employees, including supervisors and particular training for management and employee WSH representatives.

• Budget allocated for WSH training

• Average number of health and safety training days per employee

• Percentage of total workforce represented in formal joint management-worker safety committees.

• How employees are involved in health and safety management process, including identification and controlling of new hazards, work processes, accident and occupational disease investigations

7. Report on WSH progress against targets

A company that is dedicated to WSH improvement would regularly review its WSH performance to ensure it’s maintained or improved. The reporting could list out:

• New WSH innovations such as new programmes or case studies resulting in safety improvements and increased productivity and / or cost savings

• Assessment of its WSH performance against its targets

• New WSH targets for the forthcoming period

ANNEX C

ADDITIONAL REPORTING

1. Managing contractors

It is important to monitor the WSH arrangements of your contractors and suppliers as their WSH performance could adversely affect you. You should therefore address, where appropriate the WSH management of contractors and suppliers in your reporting. The report on processes in place to manage the WSH performance of contractors and suppliers could cover the following:

• Tender specifications in project requiring contractors to meet certain WSH standards

• Induction training for all contractors including supervisors and workers

• Arrangements for contractor management in the workplaces

• Introduction of awards to incentivise contractors and suppliers to achieve safety accreditation

2. Regulatory Actions

Worksite inspections may be carried out by the Ministry of Manpower arising from a complaint, the occurrence of an incident as well as proactive monitoring of specific companies’ WSH performance. Where appropriate, you should also report on any regulatory interventions, prosecutions for the reporting period and the subsequent actions taken by your company

• Amount of Composition Fines issued by Ministry of Manpower

• Number of prosecutions by Ministry of Manpower

• Number of Stop Work Order Issued by Ministry of Manpower

• Number of Remedial Orders issued by Ministry of Manpower

• Number of Notices of non-compliance issued by Ministry of Manpower

• Number of insurance claims filed

3. Other WSH Initiatives

You may wish to include additional information on your company’s WSH initiatives over and above the core information provided under Basic Reporting. The additional information on your company’s WSH initiatives for reporting could span across a wide spectrum of issues suggested in the following:

• Details of initiatives in upgrading equipment, processes or practices for WSH improvement

• Programmes to build and sustain WSH culture

• Organisation’s contribution to WSH within its industry – Representation in safety related committees, taskforces and /or groups ; invitation to share on best practices at safety events ; sponsorship of safety programmes or training and development awards

• Collaborative activities with external stakeholders such as safety-related institutions, Non-Government Organisations (NGOs)

• Inclusion of WSH issues in union agreements

• Whether the reported performance data has been independently verified by auditors

FURTHER INFORMATION ON WSH REPORTING

• Health and Safety Commission (UK); Health and Safety in annual reports: Guidance from the Health and Safety Commission, 2nd April 2001 http://www.hse.gov.uk/revitalising/annual.htm

• The National Occupational Health and Safety Commission

www.nohsc.gov.au

• Institute of Occupational Safety and Health, Guidance on including health and safety performance in annual reports

http://www.iosh.co.uk

• Victorian Workcover Authority, Occupational Health and Safety Reporting: Guidelines for reporting OHS in annual reports http://www.workcover.vic.gov.au

• Global Reporting Initiative http://www.globalreporting.org/Home

Annex D

WSH Reporting Template

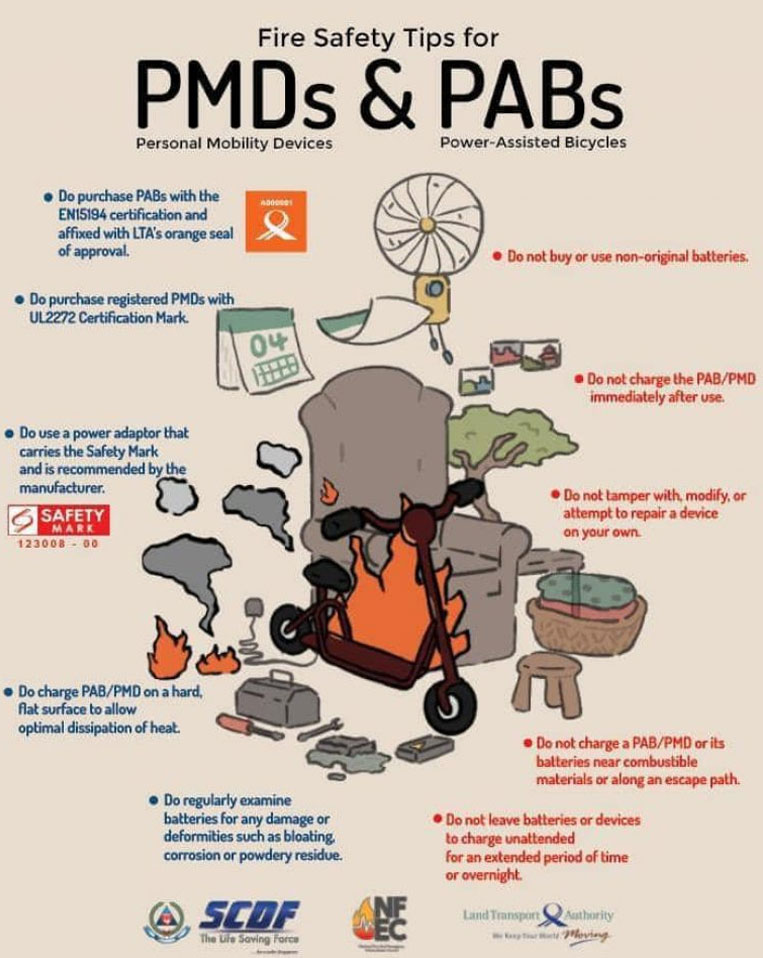

Image from SCDF on Facebook.

Image from SCDF on Facebook. Image from SCDF on Facebook.

Image from SCDF on Facebook. Image from SCDF on Facebook.

Image from SCDF on Facebook.